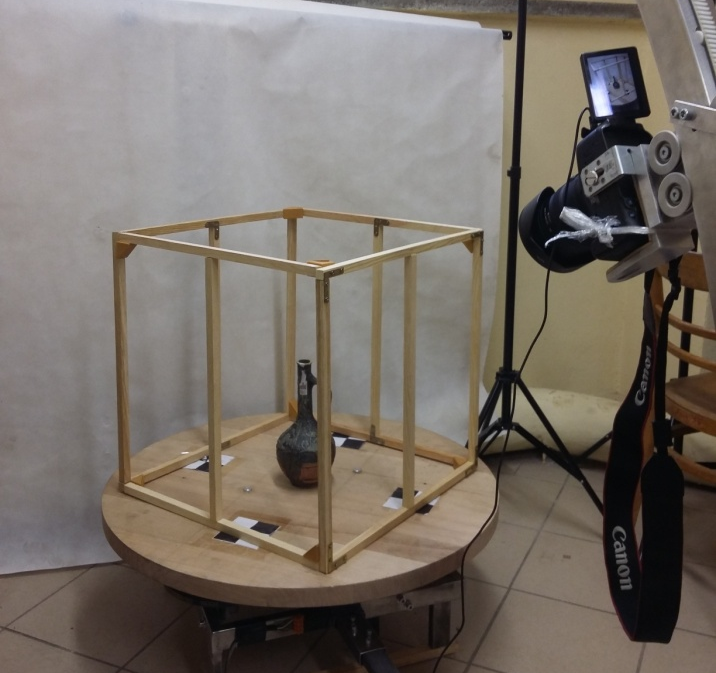

The FocusSphere is a close-range photogrammetric measurement machine consisting of a turntable, a boom with mobile trolley and a number of peripheral devices.

The object under examination is placed on the turntable surface. The FocusSphere works by making alternate movements between the turntable and trolley, thus photos of the object are taken. Next, the photographic data are used for photogrammetric purposes. In addition, an appropriate use of the light allows a stable and reliable exposure to be obtained. The screen that is placed opposite the camera, also constitutes an important element which allows irrelevant details from the background of photos to be erased. Despite its construction complexity, the device is also comprehensive. There are plenty of possibilities to control the mechanical, automatic and optical properties.

Photogrammetry ceramic vessels

FocusSphere

In the last few years, huge progress has been made in the field of computation technology. During common everyday activities like checking an e-mail correspondence with a cup of morning coffee or brewing this cup of steaming hot coffee, life has been simplified by microprocessors. The increasing computation power allows a large number of mathematical operations to be carried out in one second. These technologies have now been introduced with great success into classical photogrammetry, i.e. the field of science producing 3D models based on 2D photos. Along with the development of this methodology of three-dimensional products, new problems are being addressed. Algorithms are tools that are used to generate dense point clouds: a term used to describe laser scanning products, but in this case, a much higher number of photos is required than in the traditional aerial photogrammetry. The problem of taking large quantities of photos was the reason for the design of a device called the Automated Photogrammetric Platform FocusSphere, which makes the process of obtaining photos faster and simpler. It is a universal tool for planning and executing photogrammetric coverage; it was designed and developed by one of the current authors, W. Niewiem Msc. Eng.– PHOTOGRAMMETRIC DOCUMENTATION OF CERAMIC VESSELS Mateusz Boruchowski Paweł Ćwiąkała Małgorzata Kajzer Witold Niewiem Kamila Nocoń Edyta Puniach

Exterior orientation

Obtaining photographic data for photogrammetric purposes is not a simple task, if such data has to meet some specific conditions. Supposedly, regular coverage is one of these parameters. Acquiring several dozen or even several hundred photos is a time-consuming and tedious action, hence the FocusSphere speeds up this process and limits the required effort. Attention has to be paid to the exterior orientation, such as the coordinates of the projection centre and the direction of the lens for each moment of the process, when the photo is taken. In the 3D model calculation, the exterior orientation is particularly useful. An additional advantage of using the FocusSphere is the possibility to place control points on the turntable surface. Control points are automatically detected in photos due to the use of coded targets. Moreover, it makes the process faster and eliminates the human factor, which is the most common reason of errors. The most important of many advantages of the device are: non-invasive handling (it could easily be used to document delicate ancient objects) and high accuracy camera positioning (about 1 mm).

The photogrammetric documentation

The photogrammetric documentation of ancient vessels can take several steps. First of all, it is important to ensure an appropriate preparation of an object i.e. to position an object on a table to ensure stability. It is necessary to mark or to point natural, additional control points on vessels. Secondly, photogrammetric data is obtained by the FocusSphere for each vessel. This data has to consist of two positions of an object: firstly, in a starting position (the vessel is on its base) and secondly, in the upside-down position (the vessel is on its rim); in both positions, a total of 80 photos are taken. The last stage is a computation in Agisoft Photoscan software, in order to acquire the dense point cloud and the mesh model, together with a photorealistic texture representing the object. These final products of photogrammetric documentation could be used for further analyses e.g. cross-sections and longitudinal sections, outlines of the vessel’s cross-section or 3D printing of the object.